How do edgelit acrylic signs work?

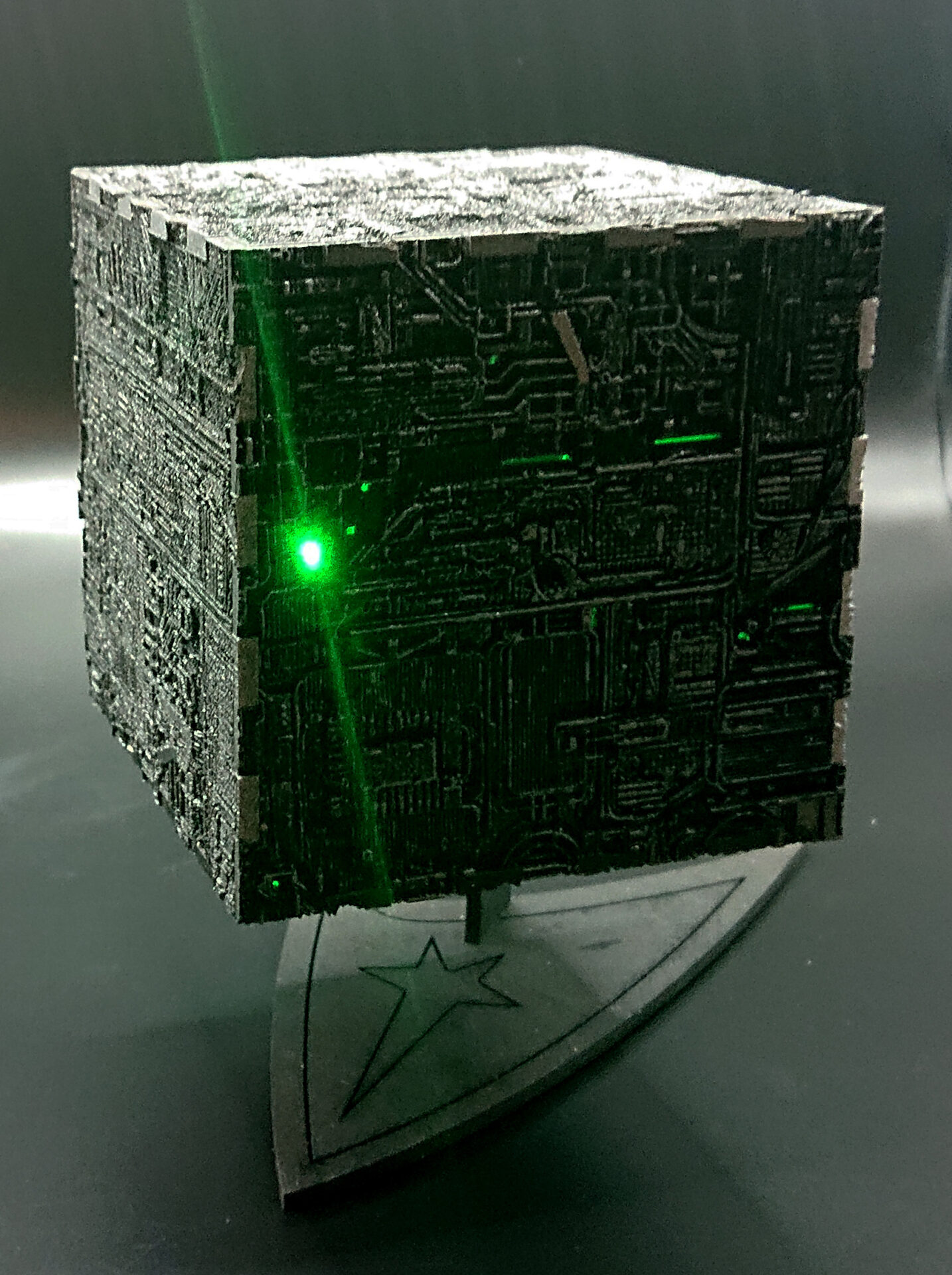

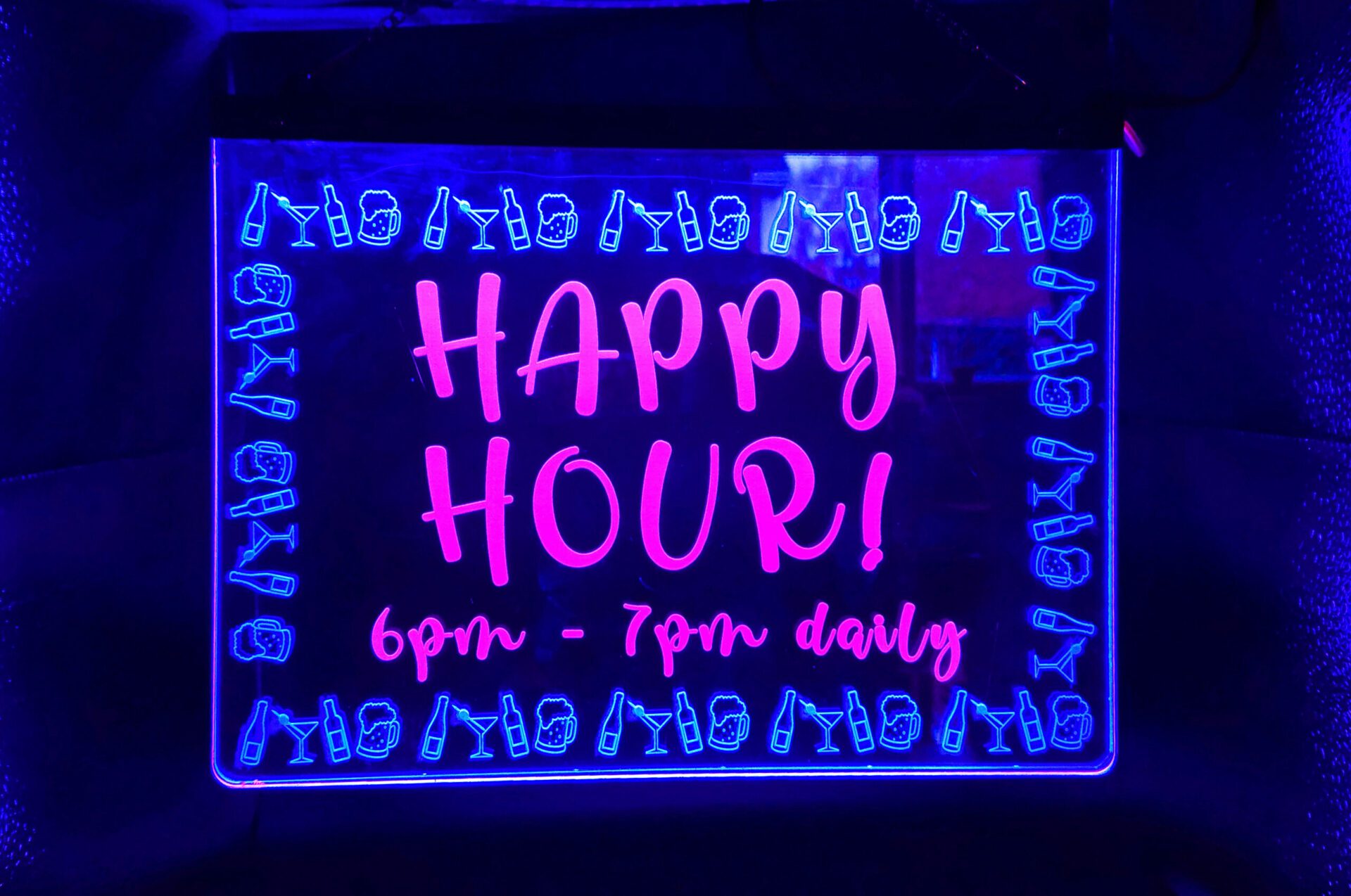

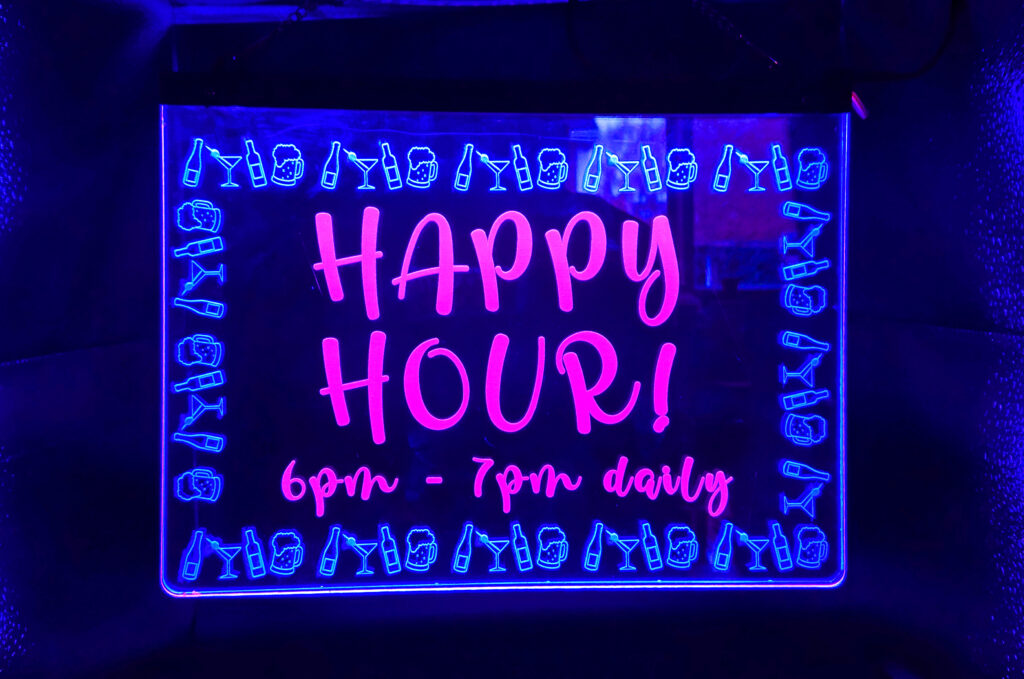

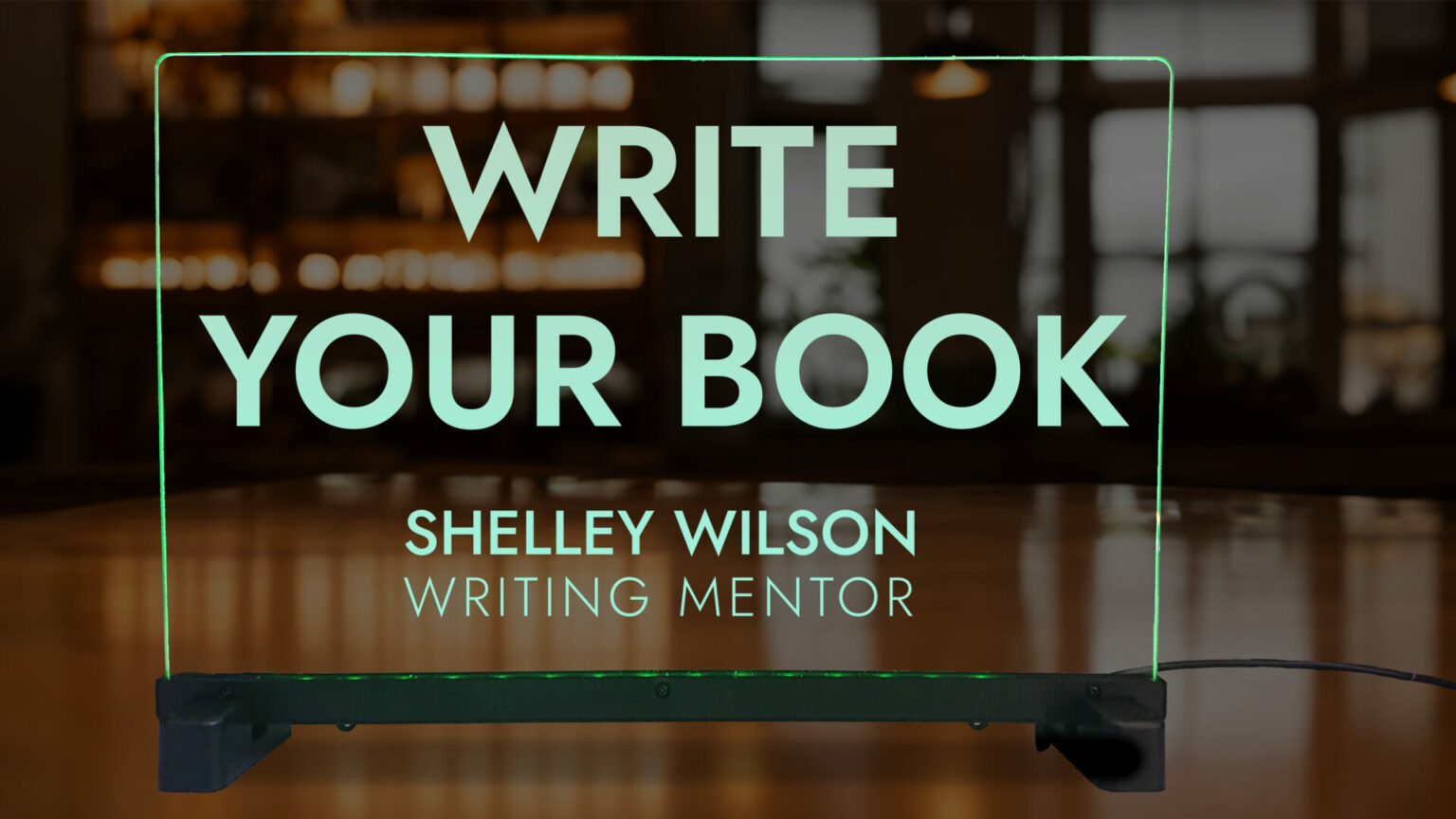

You’re probably familiar with edgelit signs, if you’ve spent any time browsing our site then you’ve definitely seen them. They’re those signs which are made from engraving a (usually) clear acrylic plate with a design and then shining a light source, like an LED, through the acrylic, but what makes them work?

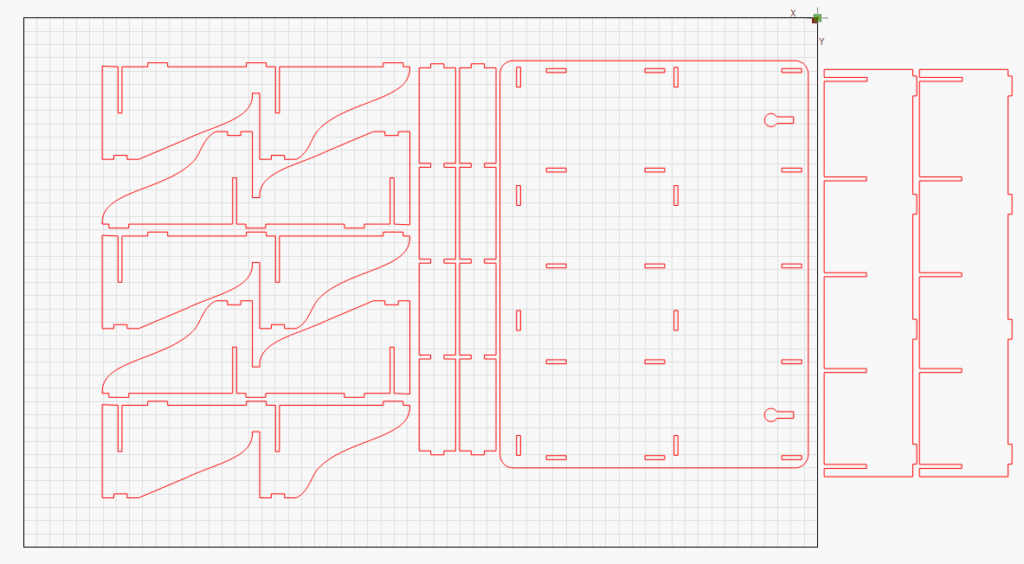

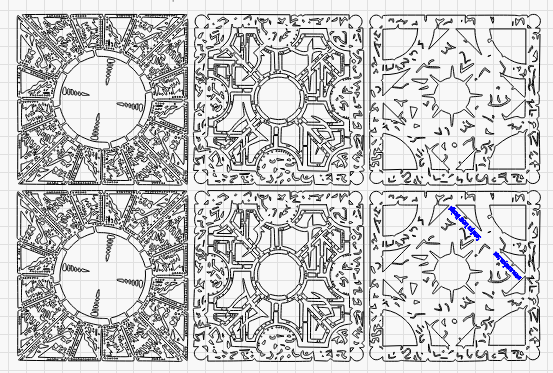

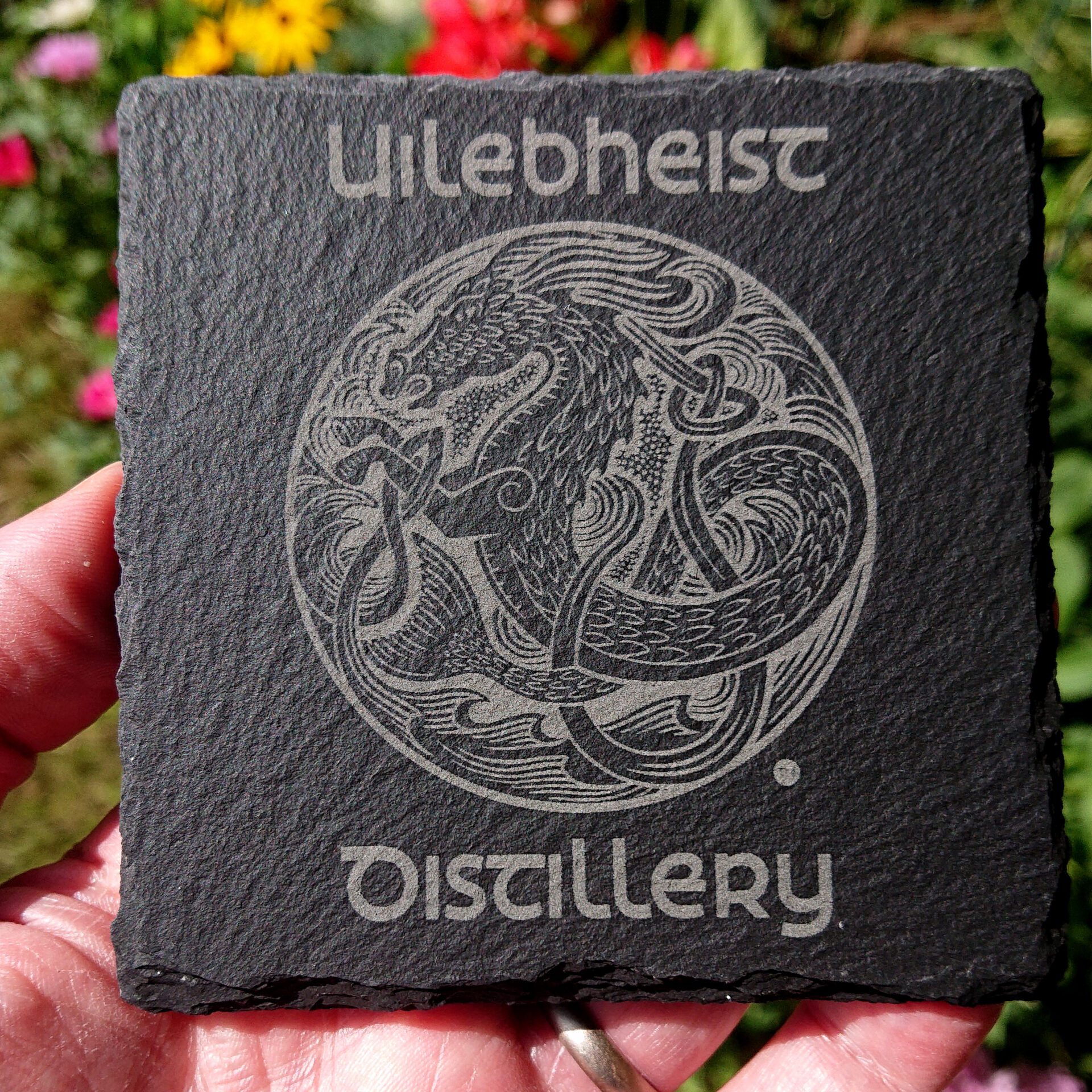

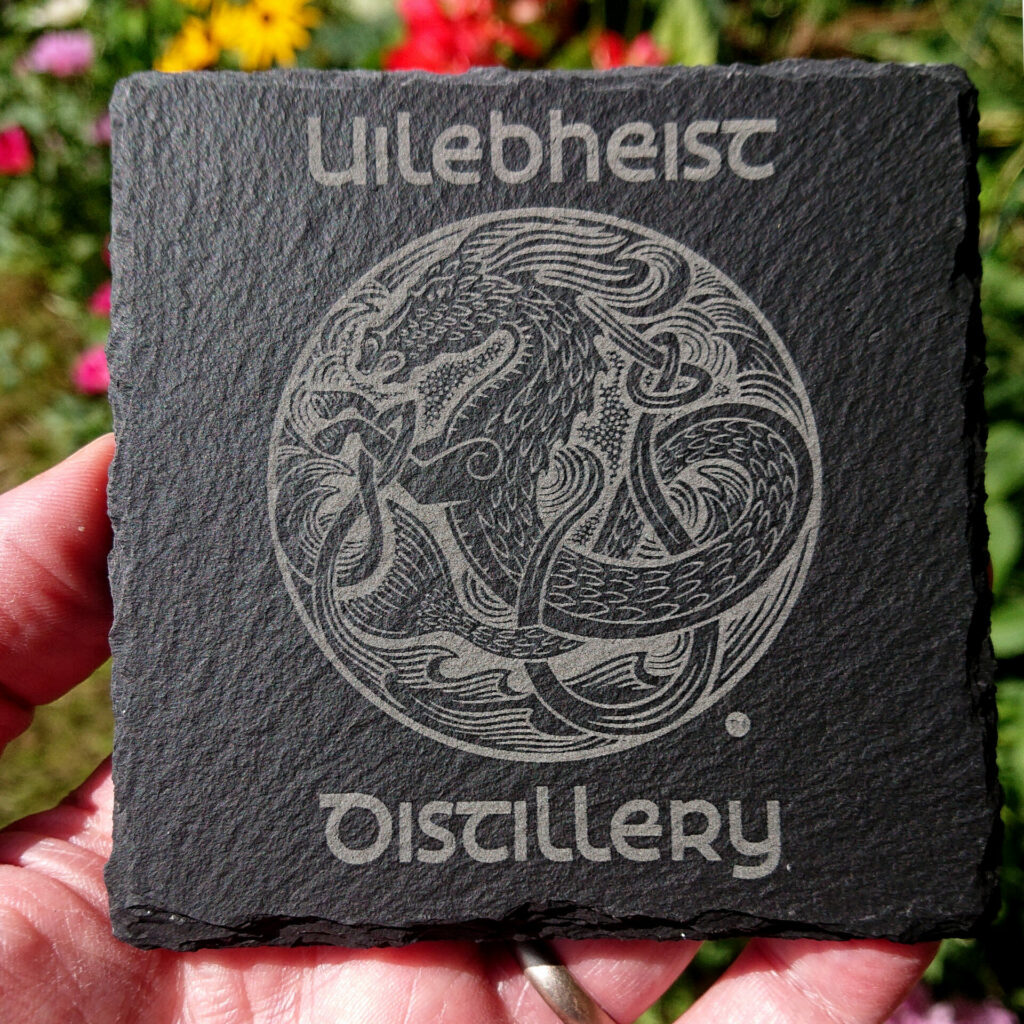

First, engrave it

When you engrave acrylic with a laser the surface turns from a reflective gloss to a frosted white/lighter colour. This is the same whether the piece of acrylic is translucent or not though obviously the effect is a little different. While you can’t meaningfully shine light through the opaque coloured types of acrylic the clear and translucent types are formulated to transmit light in particular ways. While you can use the flourescent types of acrylic we’ll be sticking with normal clear acrylic sort here.

What does edgelit mean?

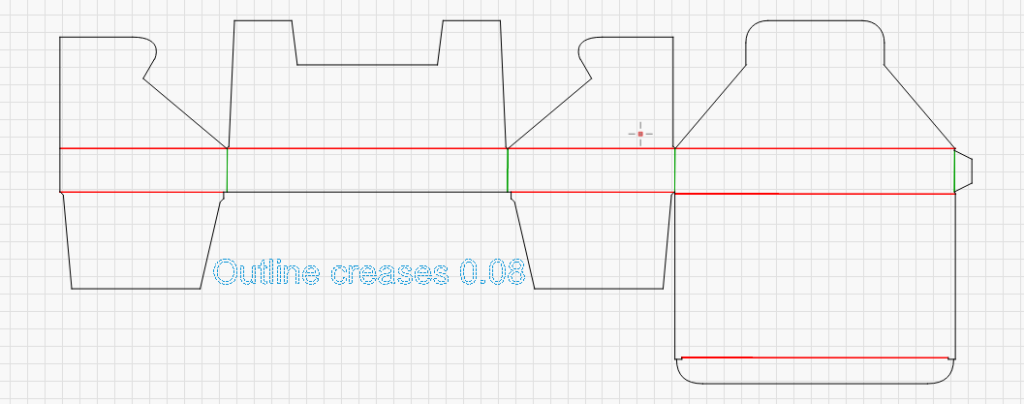

So we know that we have a piece of acrylic and it’s going to be engraved and be illuminated. You can’t just shine a light at it. Well you can but it’s not going to to create the effect we’re after. It needs to be ‘edgelit’ which is shining the light through the acrylic from the edge of the material. Unless you have extremely thick acrylic which is going to be pretty heavy, you’ll be needing a nice skinny light source. For this LED strip is perfect, it comes in widths from 3mm wide extra-skinny to around 12mm wide for the smarter addressable RGB strips and of course it all comes in a range of different colours and much of it runs on 5V which is super-convenient for powering stuff from USB. You just need to make it shine through from the edge of the material.

Get a grip

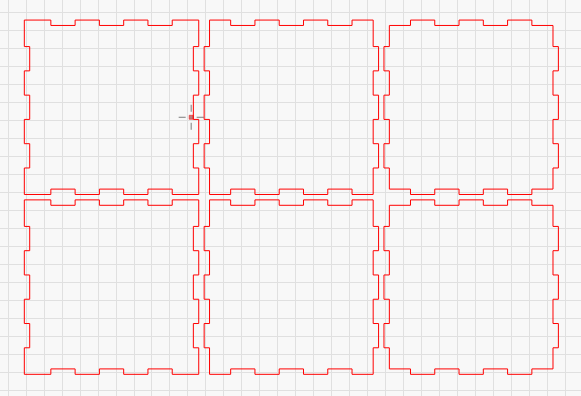

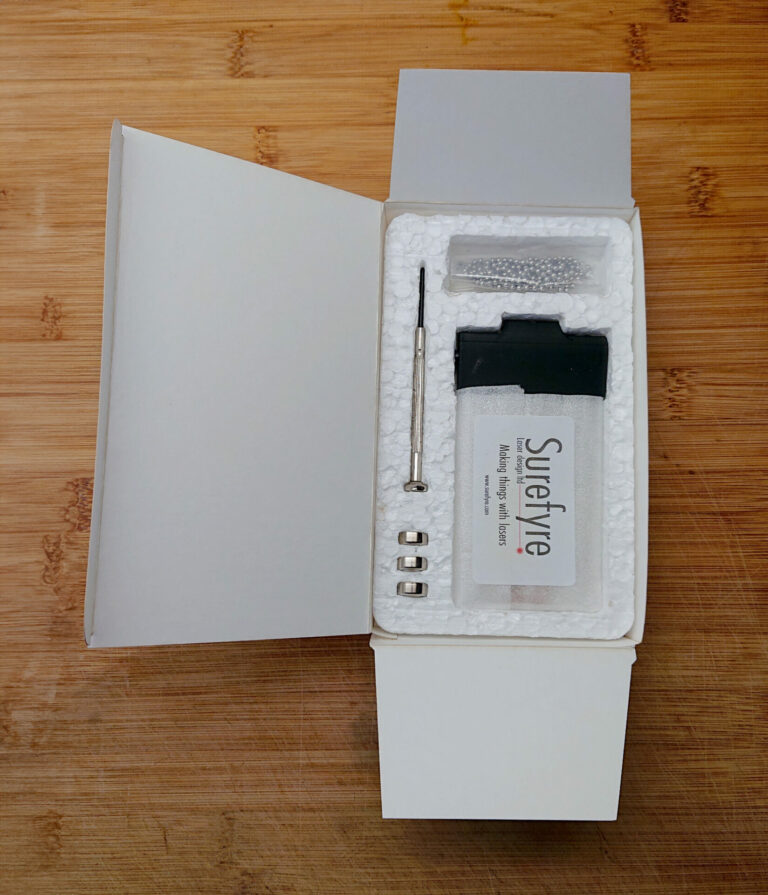

To shine the light through the acrylic you need a lighting grip, often called an LED base for signs that stand on things rather than hang or are otherwise mounted. The grip is a holder for the acrylic plate which contains the LED strip and a slot to put the plate in which has the LED shining up through it. As soon as the plate is put into the slot and the LED turned on the sign starts to do its thing. As the light bounces around inside the acrylic it will hits the engraved part of the surface. When this happens the light isn’t reflected, it’s diffused by the engraving which to the viewer appears to be illuminated so wherever there’s an engraved part of the surface it lights up. This is how the ‘hanging in the air’ effect of the illuminated sign happens.

Your name in lights

Get in touch today using our contact form or, if you prefer, grab a zoom slot for a chat at a time that suits you and let’s have a conversation about creating some attention-grabbing signage for you