We are excited to announce that Surefyre Laser Design has been selected by local charity Pass The Smile For Ben to produce their medals for an upcoming event at the end of March.

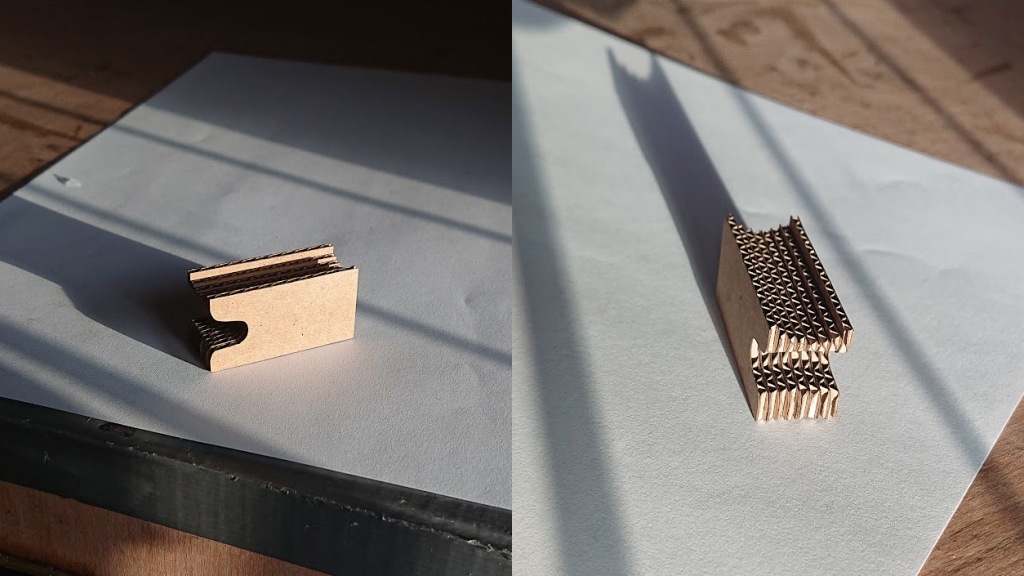

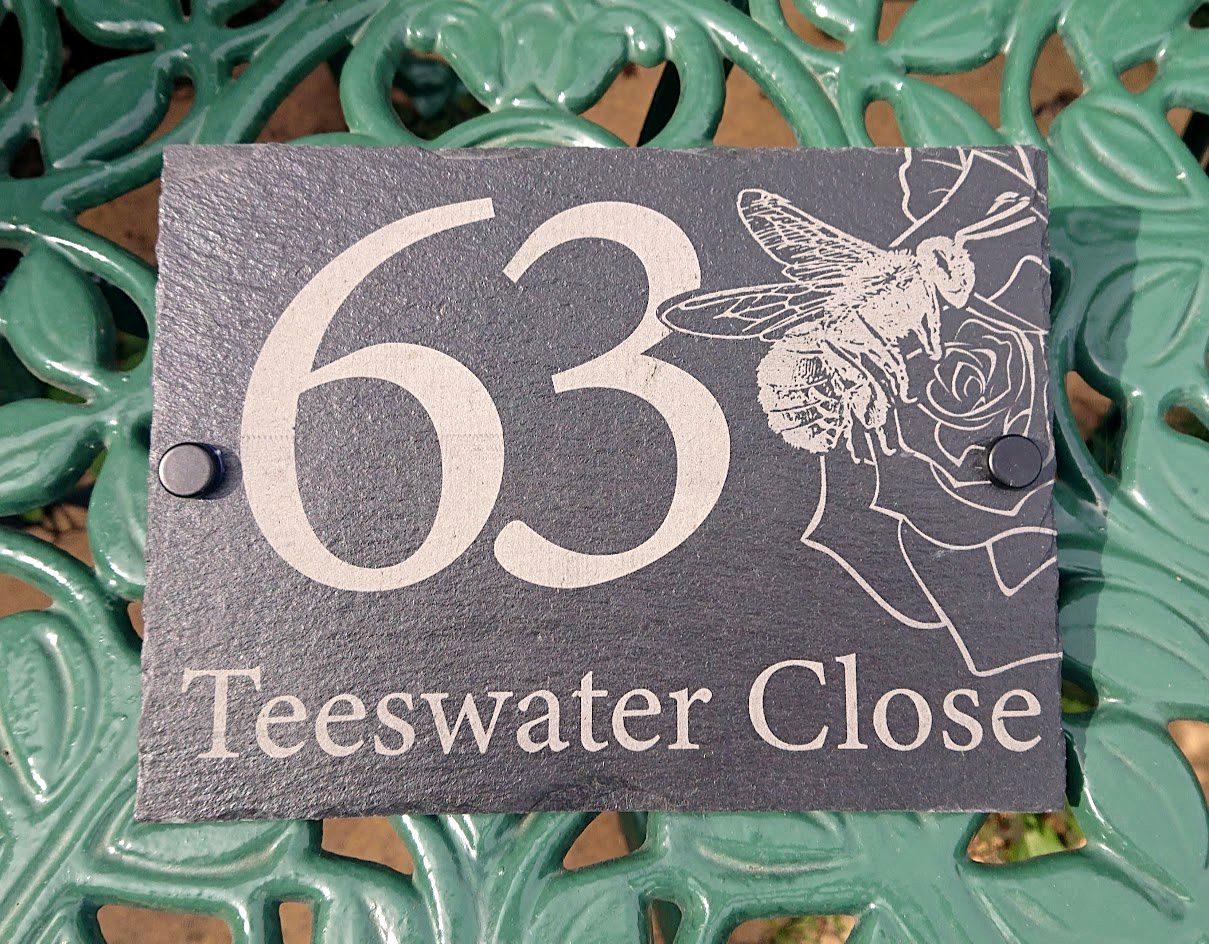

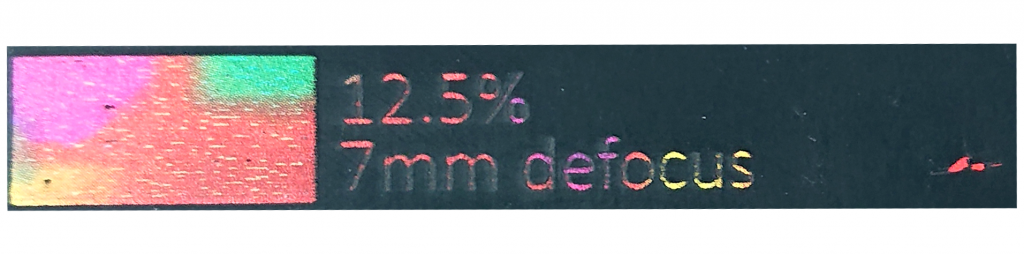

We have been asked to make 100 double-sided wooden medals which will be created from FSC-sourced recyclable ply for the event. We took a sketch concept from Pass The Smile and used that as the basis to design the medal in close consultation with the charity, it is now about to go into production for them.

Pass The Smile raises funds for research into childhood cancer in memory of Ben Crowther from Earlsdon, Coventry. Ben (aka Bennis the Menace) was diagnosed with a rare cancer, Rhabdomyosarcoma, in June 2018. Despite the brutal effects of his own chemotherapy treatment Ben tried different ways to cheer up other patients, including telling jokes and pulling pranks on friends, family and the hospital staff. Ben (age 7) gained his superhero wings just a year after diagnosis. Pass The Smile is his legacy.

Ben would have been 11 years old on 27th March 2023. The medals are for a virtual event celebrating Ben, his 7 Earth years and his heavenly age of 11. People are encouraged to join in challenges of their choice incorporating the numbers 7 or 11 – or both! You could read 7 books, run 7km, tell 11 jokes or play 11 pranks. Maybe not all at the same time though! Information about taking part will be released on Pass The Smile social media. (https://www.facebook.com/PassTheSmileOrg/)

Pass the Smile for Ben is a named fund at the Children’s Cancer and Leukaemia Group, the experts in Childhood Cancer. Registered Charity Number: 1182637

If your organisation has an upcoming event then get in touch to see how we can help you with it.